- 25,000 sq ft facility

- 7,000 sq ft clean space (class 100)

- In-house 2.5D/3D technology development

- In-house 2.5D/3D IC prototyping

- Diverse team of engineers and technicians allows operation flexibility

- 100mm, 150mm, and 200mm wafer processing

- Fab processes include photo, etch, thin film deposition, surface prep, metalization, bonding, wafer thinning, CMP, pick-and-place

- Wafer-to-wafer, chip-to-wafer, and chiplet-to-interposer bonding

- Hybrid bonding

- Micro Transfer Printing (MTP)

- Expansion in progress to add a high-volume advanced packaging line

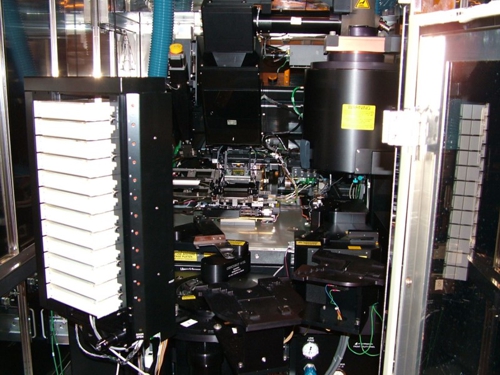

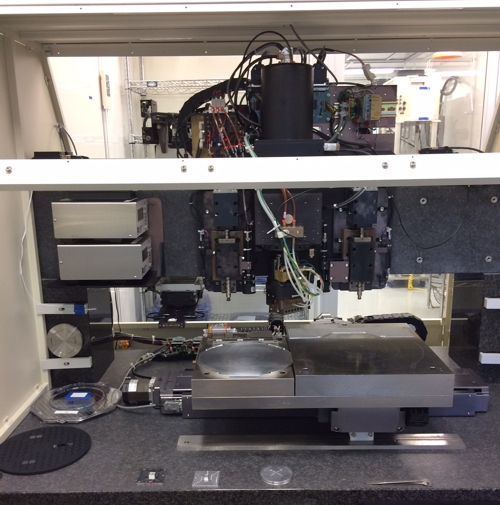

Our R&D and prototyping fab is nestled in the heart of North Carolina’s Research Triangle. The 25,000 square foot foundry includes a 7,000 square foot clean space (class 100). Our skilled staff has an admirable record of successful projects and extensive experience in process development and prototyping, including 2.5D and 3D manufacturing and the use of exotic materials. The team’s diversity allows great flexibility of operation.

The fab’s toolset is ideal for rapid prototyping with a focus on 3D-ICs and interposer assemblies. Current equipment performs photo, etch, thin film deposition, surface prep, metalization, bonding, thinning, CMP, and pick-place on wafer sizes from 100mm to 200mm. Bonding can be wafer-to-wafer or die-to-wafer and can build heterogeneous substrates. High precision process control during thinning creates multi-wafer stacks as thin as a normal die. The back-end-of-line (BEOL) has both aluminum and copper capabilities, including backside processes on thinned surfaces.

For die stacking and wafer stacking, NHanced uses the DBI®, DBI Ultra, and ZiBond® processes (developed by Ziptronix) and the FaStack® process (developed by Tezzaron). Our engineers and technicians continually improve and refine these processes, while also developing proprietary new 2.5D and 3D technologies.

The NHanced fabrication facility has achieved ISO 9001:2015 certification for its quality management system as a semiconductor process service provider.

NHanced Semiconductors is pursuing US government “Trusted Foundry” status.